Fletcher 8400 Glass and Material Cutter - Put into Action with Custom Mobile Stand

I have put most of the equipment from my big purchase of Framing equipment and supplies into use except for an Oval and Circle Cutter, a Chronomat Mat Cutter, and a Fletcher 8400 Series Glass and Material Cutter.

The Oval and Circle Cutter will stay stored until I have a need for it, but not a commonly used piece of equipment.

The Chronomat Mat Cutter is a 48” variety and older. Logan bought either the company or the product and branded as their high-end professional grade Platinum Edge line. I bought a Platinum Edge 850 40” last year and just love it. I’ll keep the Chronomat in case I need the extra length and as a backup and some of the parts are interchangeable which could come in handy one day.

The Fletcher 8400 Series Glass and Material Cutter is an older one but like so much framing equipment, age doesn’t really matter, mostly condition. It has enough extra cutters and blades to last beyond my need.

I have been brainstorming how I can get it into use. The challenge is that my workshop resides in a storage facility where I have 3 units…1 for frame joining and woodwork, 1 climate controlled for mounting and assembly (and eBay inventory/shipping), and 1 for moulding, glass, and mat board inventory and supplies. You see the challenge is that these cutters are intended to be wall mounted and that isn’t possible in a storage unit with metal walls.

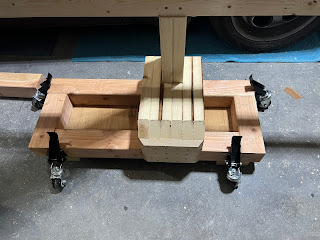

After much deliberation on what to do, I landed on the direction of creating a portable stand. So off to Lowe’s I went this morning at 7am and at 10:30pm I ended up with what you see at the top of the post.

I more or less had a general design in my head although it ended up being a very fluid design. I ordered some retractable casters as I wanted to be able to move easily yet be able to plant it stationary when in use. I ended up gluing and screwing anchor bolts on most of it, but did allow for it to be disassembled should the need arise…the base, the vertical mast, and the cross bar. The cutter leans a few degrees back to allow the glass being cut to lean in place.

The end result was perfect for my need and is very stable. I put the castors in the odd locations so it can be pushed flush with a wall to increase stability further. I’ll try it out tomorrow!

Comments

Post a Comment

No URLs, I delete comments which appear to be be advertising.